|

| December 15, 2015 | Volume 11 Issue 47 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Discovery of ‘stainless magnesium' could spur design revolution for transportation

Researchers led by a team at the University of New South Wales (UNSW Australia) have used the Australian Synchrotron (particle accelerator) to turn the discovery of an ultra low-density and corrosion-resistant magnesium alloy into the first step toward mass-producing "stainless magnesium," a new high-strength, lightweight metal.

The discovery aims to pave the way for cars, trucks, and airplanes that can travel further distances on less fuel.

The Australian Synchrotron is a world-class national research facility that uses accelerator technology to produce a powerful source of light (X-rays and infrared radiation) a million times brighter than the sun.

The magnesium-lithium alloy weighs half as much as aluminum and is 30 percent lighter than magnesium, making it an attractive candidate to replace these commonly used metals to improve fuel efficiency and greatly reduce greenhouse gas emissions from transport vehicles.

The findings, published Oct. 19 in Nature Materials with researchers from Monash University in Melbourne, Australia, describe how the alloy forms a protective layer of carbonate-rich film upon atmospheric exposure, making it immune to corrosion when tested in laboratory settings.

Professor Michael Ferry, from UNSW's School of Materials Science and Engineering, says this formation of a protective surface layer can be considered similar to the way a layer of chromium oxide enables the protection of stainless steel.

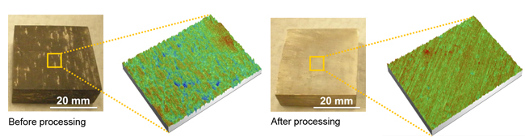

The surface condition of two samples of the magnesium-lithium alloy following immersion for 20 hours in salt water, one after being heat-treated and water quenched, and the other without processing. In previous magnesium-lithium alloys, irreversible corrosion would have set in after such time, but clearly visible in this optical profilometer image, the surface of the processed alloy remains in near pristine condition.

"This is the first magnesium-lithium alloy to stop corrosion from irreversibly eating into the alloy, as the balance of elements interacts with ambient air to form a surface layer which, even if scraped off repeatedly, rapidly reforms to create reliable and durable protection," says Ferry.

Ferry, senior author of the paper led by UNSW's Dr Wanqiang Xu, says this excellent corrosion resistance was observed by chance, when his team noticed a heat-treated sample from Chinese aluminum-production giant CHALCO sitting, inert, in a beaker of water.

‘To see no corroded surfaces was perplexing and, by partnering with scientists on the Powder Diffraction (PD) beamline at the Australian Synchrotron, we found the alloy contains a unique nanostructure that enables the formation of a protective surface film," says Ferry. "Now we've turned our attention to investigating the molecular composition of the underlying alloy and the carbonate-rich surface film to understand how the corrosion process is impeded in this ‘stainless magnesium.'"

Professor Nick Birbilis, School of Materials Science and Engineering at Monash University, says viewing unprecedented structural detail of the alloy through the Australian Synchrotron will enable the team, involving researchers from Monash University, CHALCO, and Nanjing University of Technology in China, to work toward commercializing the new metal.

"We're aiming to take the knowledge gleaned at the Australian Synchrotron to incorporate new techniques into the mass production of this unique alloy in sheets of varying thickness, in a standard processing plant," says Birbilis. ‘These panels will make many vehicles and consumer products much lighter and, eventually, just as durable as today's corrosion-resistant stainless steel, another example of how advanced manufacturing is unlocking the potential of materials that have been under investigation, in too narrow a manner, for centuries."

Source: Australian Synchrotron

Published December 2015

Rate this article

View our terms of use and privacy policy